- Home

- how to Install Industrial Cold Room

how to Install Industrial Cold Room

Industrial Cold Room Installation Instruction

Industrial Cold Room includes two main parts, insulation part and refrigeration part. Following is the installation instruction of CASGYW cold room.

1.1 Industrial Cold room panel material

The insulation material of CASGYW Industrial cold room is polyurethane foamed composite insulation boards with spray-coated steel plates or stainless steel plates, with different thickness for different room temperature. Insulation material is flame-retardant, non-chlorofluorocarbons. Add a certain proportion of reinforcing materials to improve performance, but will not therefore reduce the thermal insulation properties.

1.2 Industrial Cold room panel installation requirement

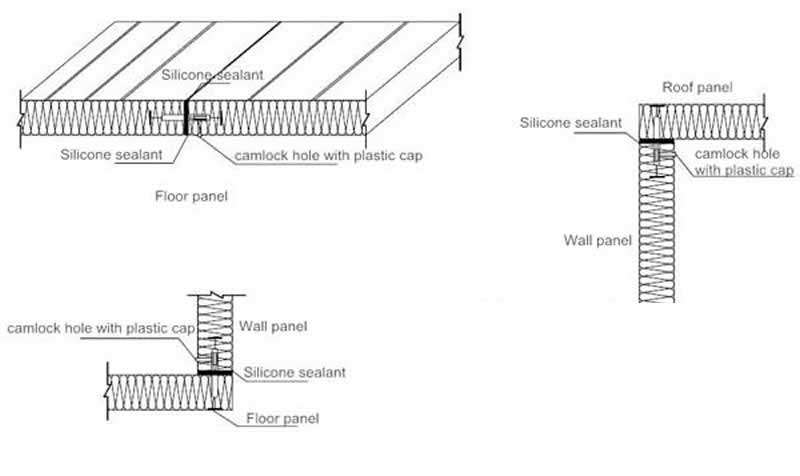

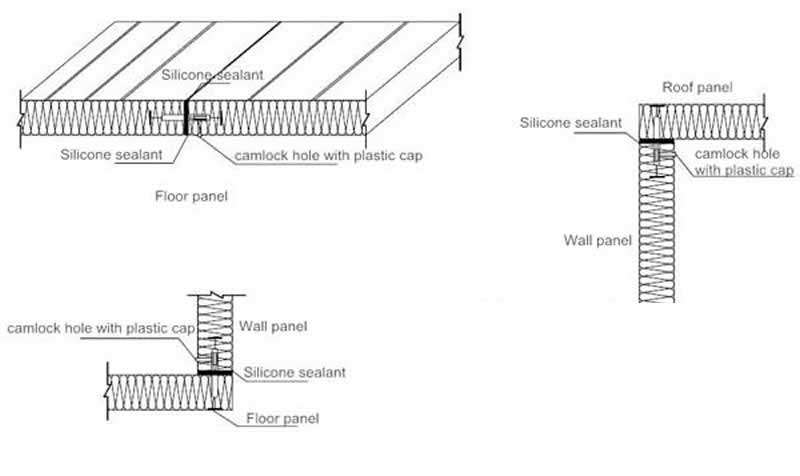

The seam between cold room panels must be sealed well, and the joint seam between the two panels is less than 1.5mm. At the same time, the structure is required to be solid and reliable. After assembling, all the joints of the cold room panels should be coated with a silicone sealant. Following drawing for your reference.

When the roof panel span exceeds 6m or the ceiling of the cold storage is heavy, the ceiling of the cold storage must be hanged. The position of the bolts should be selected from the middle point of the cold room panel. In order to keep the cold room panel to be as even as possible, the mushroom type screw, hanger and U-shaped channel steel must be used for fixing according to the diagram.

1.3 Industrial Cold room door

1) The door frames of low-temperature industrial cold room should be embedded with electric heating to prevent the sealing strips of the doors from being frozen. When electric heating is used, electric heating protection devices and safety measures must be provided.

2) The industrial cold room door has a door lock and the door lock has a safety unlocking function, we call it escape device.

1.4 Accessories

1) The interior of the warehouse is equipped with moisture-proof and explosion-proof LED lamps, which can work at low temperature. The lampshade should be damp-proof, anti-corrosion, anti-acid and anti-alkali. The degree of lighting in the industrial cold room should meet the requirements for the entry and exit of goods.

2) Pipeline holes must be sealed, moisture-proof and heat-insulated.

3) Industrial cold room should have a pressure balance device to prevent and eliminate the pressure difference between the cold room and outside.

4) Control panel requires installation near the Kumen.

5) Drainage floor drains must be installed in the freezer to allow the sewage to drain when cleaning the cold storage.

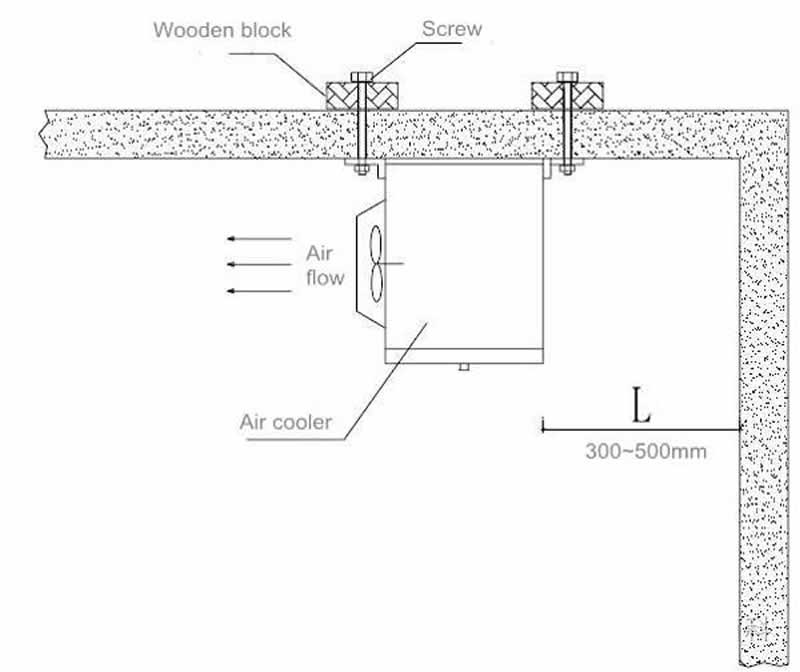

2.1 Installation of air cooler

1) The installation position of the air cooler shall be far away from the cold room door, and in the middle of the wall, the air cooler shall be kept horizontal;

2) The cooling fan is mounted on the top panel or the steel frame of warehouse, and its fixing must use a special nylon screw (material nylon 66) to prevent cooling capacity leak;

3) When fixing the air cooler with bolts, it is required to install wooden blocks with a length of more than 100mm and a thickness of more than 5mm on the top panel to increase the load-bearing area of the storage panel.

4) The distance between air cooler and the back wall is 300-500mm.

5) The wind direction of the air cooler cannot be reversed to ensure that the cooler blows outward;

6) When the refrigerator defrosts, the fan motor must be disconnected to prevent hot air from blowing into the cold room when defrosting;

7) The height of goods should be at least 30cm below the bottom of the air cooler.

2.2 The installation of refrigeration pipe

1) When installing the expansion valve, the temperature-sensing package must be fastened to the upper part of the horizontal return pipe, and ensure good contact with the return pipe. Heat insulation should be provided outside the return pipe to prevent the temperature from being influenced by the temperature of the storage tank.

2) Install the oil return bend at the bottom of the riser pipe before the chiller return pipe climbs out of the warehouse;

3) When a processing room shares a unit with a cold room or medium-temperature cabinet, an evaporation pressure regulating valve must be added before connecting the re-circulating line of the refrigerated processing room with other refrigerating or medium-temperature cabinet pipes;

4) Each cold room must be equipped with separate ball valves on the return air pipe and the liquid supply pipe for debugging and maintenance.

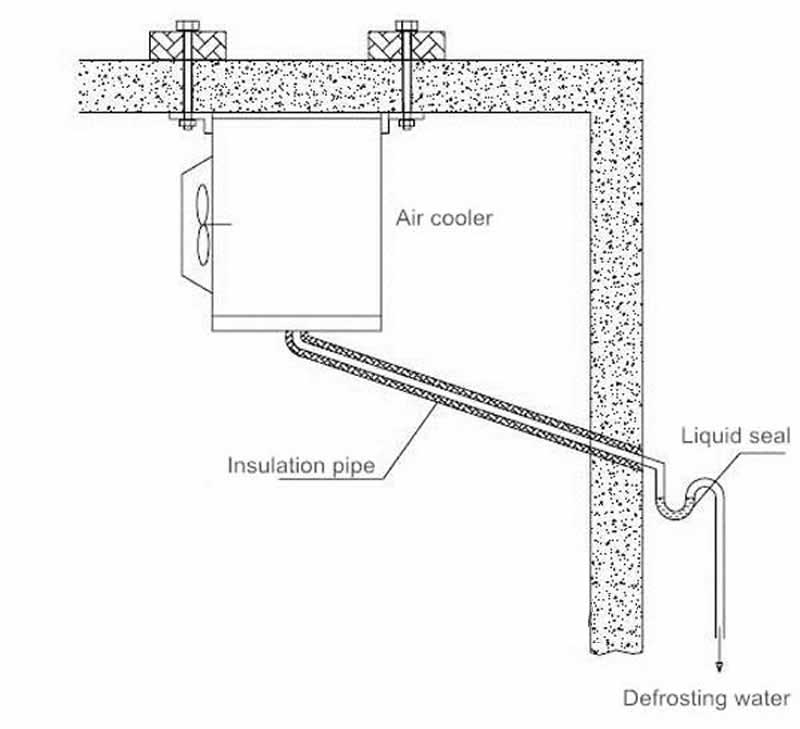

2.3 The installation of water drainage pipe

1) Drainage pipelines running in the cold room should be as short as possible.

2) The cold room’s drainage pipe should have a certain slope, so that the defrost water can be smoothly discharged outside the storehouse;

3) The cold storage with working temperature less than 5°C must be equipped with insulation pipe (thickness greater than 25mm) in the drain inside the warehouse;

4) Heating wire must be installed in the freezer drain;

5) Connection pipes outside the cold storage must be installed with drainage traps to ensure a certain liquid seal in order to prevent large amounts of hot air outside the library from entering the cold storage;