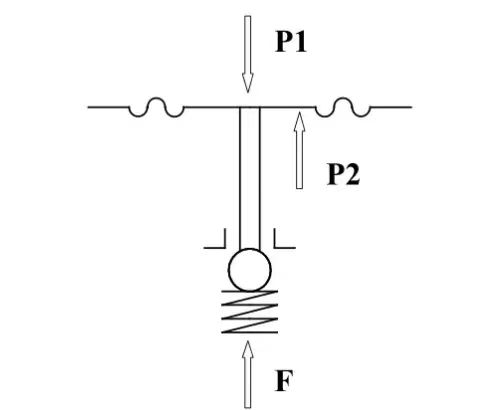

Thermal expansion valve is mainly composed of sensing mechanism, executing mechanism, adjusting mechanism and valve body. When the temperature of the bulb decreases, P1 < P2+F, the valve opening decreases and the refrigerant flow decreases proportionally. When the temperature of the bulb rises, P1 > P2+F, the valve opening increases and the refrigerant flow increases proportionally.Thermal expansion valve is an important automatic control component of refrigeration system, which is divided into external balance type and internal balance type according to different balance modes. It is generally installed between the liquid storage tank and the evaporator. It uses the temperature change of the temperature sensing bulb as a signal to adjust the opening of the valve and change the refrigerant flow, so that the medium-temperature and high-pressure refrigerant can be throttled into low-temperature and low-pressure wet steam, and then the refrigerant absorbs heat in the evaporator to achieve refrigeration effect.

1, The role of thermal expansion valve

Throttling and depressurizing

Throttling and depressurizing the high-temperature and high-pressure refrigerant condensed by the condenser to become a low-temperature and low-pressure vapor-liquid mixture which is easy to evaporate, and enters the evaporator for evaporation to absorb external heat;

Regulated discharge

According to the temperature signal obtained by the temperature sensor, the thermal expansion valve can automatically adjust the refrigerant flow into the evaporator to meet the needs of the changing refrigeration load;

Maintain a certain degree of overheating, prevent liquid hammer and abnormal overheating.

The thermal expansion valve makes the evaporator have a certain degree of superheat by adjusting the flow rate, which ensures the effective utilization of the total volume of the evaporator and avoids the liquid hammer caused by the liquid refrigerant entering the compressor; At the same time, the superheat can be controlled within a certain range to prevent abnormal overheating.

2. Composition and working principle of thermal expansion valve

| The first four years of use | Five to eight years | Nine years later |

| 1 time per year | 2 times per year | 3 times per year |