HOW TO CHOOSE INDUSTRIAL WATER CHILLERS

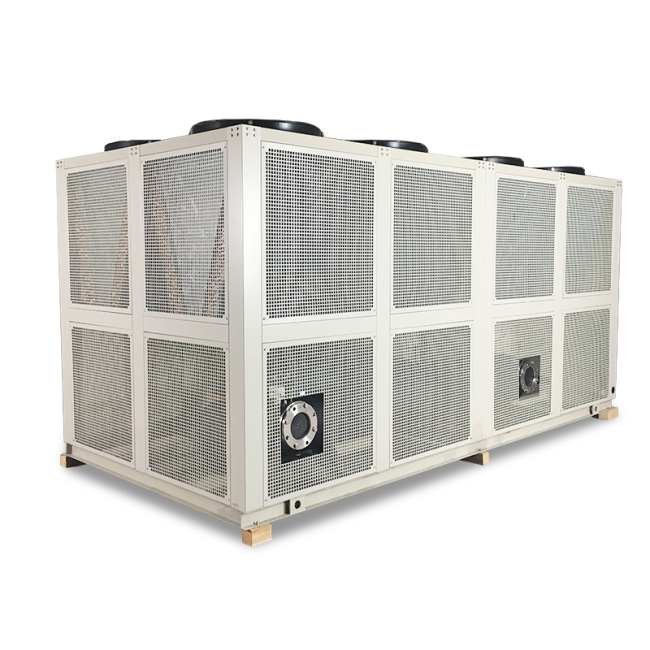

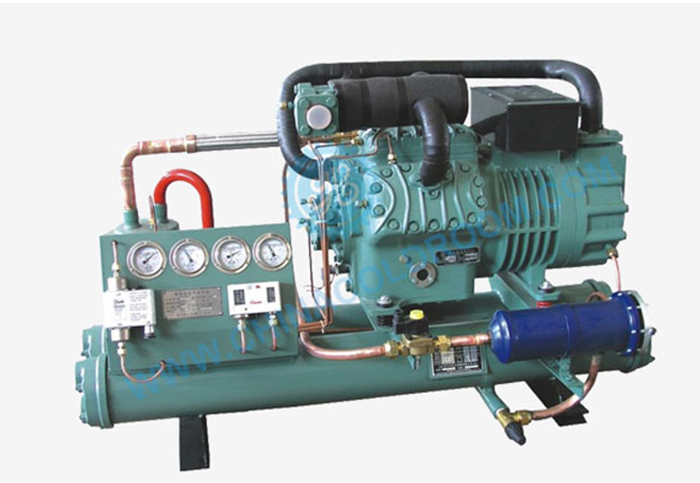

Industrial water chiller is a machine specially designed to cool the temperature of machines in large factories and industrial offices. They are used in various applications. There are a large number of water chillers to choose from on the market, and it is an important requirement to choose among them according to the needs of your […]